A sappy love story

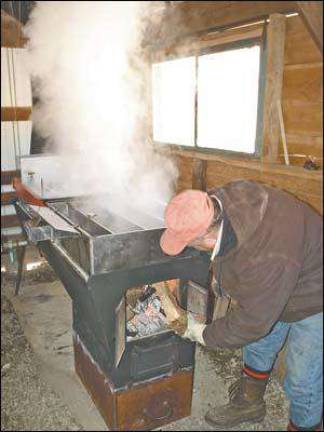

Volunteers make maple syrup from local trees, By John Church Wantage If someone says “maple syrup doesn’t grow on trees” they are right. It grows in trees. But it all starts with sap, which will flow from the maple tree when circumstances are right. A group of volunteers went to the source at Lusscroft Farm, where they collected 45 gallons of sugar maple sap to provide the raw material for a maple syrup making demonstration Saturday. “The sugar content of the sap is about 1.5 percent,” commented volunteer Roy Rohel of Branchville. “It was too cold on Wednesday and Friday. The sap froze and wouldn’t flow. Thursday we had a good day. The temperature was about 40 degrees and we collected 45 gallons.” How it’s done A tree is tapped by drilling a 7/16-inch hole and hammering in a metal spout that has an attached hook to hang a container on. A tree over 10 inches in diameter will get one tap, a 15-inch tree may have two taps and a tree over 20 inches may have three taps. The taps are spaced a minimum of six inches apart around the tree and at least two inches apart vertically. “You have to be careful that you don’t drive the tap in too deep and crack the surrounding wood,” said Frank Hennion of the N.J. Forest Service. “The sap will leak out from the cracks and not out of the spout.” Traditionally covered buckets were used to catch the slowly dripping sap. Specially designed plastic bags have been replacing the buckets. Both methods are still very labor intensive. On large production farms plastic piping is connected to the tree taps and a pump moves the sap from all the trees to a central container. “We practice proper tree land management for the target species to give the trees room to grow,” said Hennion. “Sugar maples are native to this area. This is about the southern limit for the species.” The sweet stuff Generally, a healthy tree with a large crown produces sap with higher sugar content. Trees growing too close together do not develop enough leafy area and will produce sap with lower sugar content. At last weekend’s event, volunteers gathered the sap and poured it into an elevated holding tank outside the sugarhouse. The sap has to be processed as soon as possible. “It has to be handled just like milk,” said Hennion. “It has to be kept cold and can’t be stored very long. If it gets warm it starts to ferment and then it has to be discarded.” To start the processing, the sap flowed into a series of heated evaporator trays to simmer out some of the water. A fire under the pans was fed from a large pile of firewood stacked nearby. “You don’t want to burn it. You can ruin it real quickly if you are not careful,” said Rohel. “It takes 43 gallons of sap to make one gallon of syrup. This first stage takes out 50 percent of the water.” As the water evaporated the formerly clear sap took an amber hue. Rohel drained off some of the thickened sap and replaced it with raw sap to keep the process going non-stop. The drained sap was transferred to a large pot to finish the evaporation process. “You don’t want to boil it,” said a volunteer from Wantage named Barret, as he monitored the pot of thickening sap. The syrup was just about done as it approached 66.9 percent sugar content. “Honey and maple syrup are the only two products that do not require an USDA industrial kitchen approved by the Board of Health. The equipment is cleaned with a 10 percent Clorox solution and the product is bottled at 185 to 200 degrees, killing any germs,” said Hennion. All about syrup It takes 43 gallons of sap to make 1 gallon of syrup. In a good season, one tree can produce 8 gallons of sap. Trees need to be 40 years old and 10 inches in diameter before they can be tapped. How many taps? 10-inch tree: 1 tap 15-inch tree: 2 taps 20-inch tree: 3 taps Sap can be collected until a tree shows buds in the spring. Local sap is 1.5 percent sugar Vermont sap is 3 percent sugar Syrup is 66.9 percent sugar